Every CAM programmer strives for higher productivity. Soon, AI will make this possible by helping interpret 3D geometries, recognize machining features, suggest proven machining strategies, and recommend tools based on industry practices.

Ceren Altun, Senior Business Developer, shares in a video how AI will reshape CAM programming and transform part manufacturing.

Artificial Intelligence is transforming every industry, and part manufacturing is no exception. But the complexity of modern manufacturing, mass personalization, and shorter development cycles are pushing traditional CAM programming to its limits. GenAI exists, but it is built for text and images and not suited for the demands of industry.

Industrial AI is stepping in to change the game. It interprets complex 3D geometries, suggests machining strategies, optimizes workflows, and anticipates potential quality issues. In CAM programming, it reduces programming time, improves accuracy, and frees engineers to focus on the creative and strategic challenges that drive innovation.

With rising quality expectations, sustainability requirements, and workforce shortages, part manufacturers need smarter approaches to stay competitive. Industrial AI delivers exactly that.

Why AI in CAM Programming matters and Why It matters now

One of the most acute bottlenecks in part manufacturing today is CAM programming. It is a highly specialized skill that takes years to master, and the shortage of experienced programmers slows production, limits flexibility, and puts immense pressure on a shrinking pool of experts.

Automation by using advanced programming has helped to some extent, but it often struggles with unique or complex designs. Industrial AI changes this dynamic. Instead of manually defining every strategy, CAM programmers will be able to interact directly with AI. It can analyze 3D parts, suggest machining strategies, and provide insights that traditionally relied on years of hands-on experience, elevating the entire CAM programming process. Imagine querying the AI for the most efficient toolpath, requesting an alternate strategy for tight-tolerance areas, or asking why it selected a specific feed rate—and getting an answer backed by machining intelligence.

At Hannover Messe 2025, Ceren Altun, Senior Business Developer and Deputy Team Lead for Part Manufacturing at Siemens, shared how AI will reshape CAM programming and part manufacturing. Watch the video for more insights:

The Key areas where AI transforms CAM programming

Industrial AI is reshaping the way NC programming is approached, helping programmers work faster, smarter, and with more confidence. Here are the areas where it can make a tangible difference:

Smarter 3D Part Interpretation

Too often, valuable time is lost in the early stages of programming when dimensions and features are checked manually. AI can step in here. It can analyze the 3D model instantly, highlight the critical details, and give programmers a head start. That means the first step of machining becomes more about strategy and less about searching for details.

Faster Feature Recognition

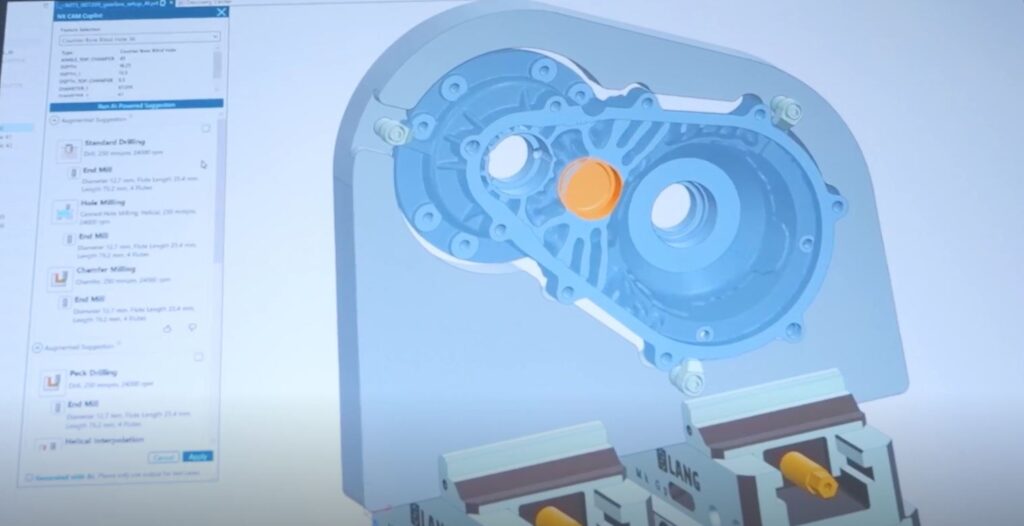

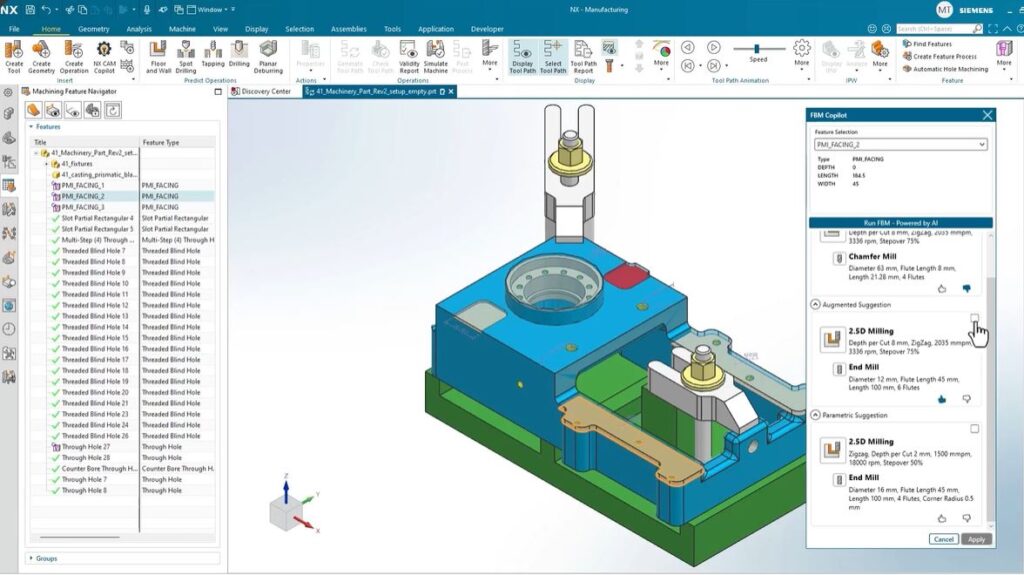

Feature recognition is not new, but AI can elevate it. Instead of just spotting pockets, holes, and surfaces, it can understand how these shapes connect to machining intent. The result is faster, more accurate identification of features—even the complex ones that traditionally required an expert’s eye.

Proven Machining strategies, Suggested Instantly

Toolpath selection has always been guided by experience. AI introduces something new: the ability to recommend strategies that worked on similar parts in the past. Imagine roughing, finishing, or adaptive machining strategies surfaced instantly, reducing trial and error and helping programmers feel more confident in their choices.

Context-Aware Tool Guidance

Tool choice is often the difference between a program that delivers efficiency and one that falls short. With AI, tool recommendations can be context-driven—matched precisely to the material, geometry, and requirements of the job. No more digging through libraries; instead, suggestions arrive at the right moment, tailored to the task at hand.

This is not about replacing expertise. It is about helping experts work smarter with better insights and guidance, so they can focus on bigger challenges. When used wisely, AI can make programming more strategic and creative instead of a series of repetitive tasks.

How Siemens is driving the future of Industrial AI that thinks like an Engineer

At Siemens, we are developing an Industrial AI foundation model that doesn’t just process data—it understands engineering and the practical realities of part manufacturing. A large-scale generative AI, like well-known models like GPT, but specifically fine-tuned for the industrial world.

Unlike GenAI, this model learns from:

• Industry best practices

• Proven manufacturing methods and standards

• Real-world engineering challenges

• Successful past projects

This AI thinks like an engineer, NC programmer, bridging the gap between knowledge locked in experts’ heads and the day-to-day demands of modern manufacturing. Users will be able to interact with the model directly through natural language, receiving precise answers about 3D parts, machining strategies, and programming questions.

“We are not just automating CAM programming, we are democratizing manufacturing expertise.”

Ceren Altun, Senior Business Developer, Siemens

A New Era of Manufacturing Intelligence

Faster. Smarter. More accessible.

For experienced programmers, industrial AI can eliminate repetitive effort and free them to focus on innovation. For newcomers, it can lower the barrier of entry, guiding them with the same precision as a seasoned expert. For manufacturers, it can mean higher-quality parts, delivered faster, with fewer errors.

But this is bigger than just speeding up programming. We are not simply automating CAM. We are transforming it. By combining domain expertise, AI reasoning, and decades of engineering best practices, Siemens is creating a future where manufacturers can overcome complexity, outpace disruption, and address skill shortages head-on.

The age of industrial AI has begun. And it is designed to think like an engineer.