The latest NX update enables you to create better designs faster and with greater confidence.

- Provides you deeper design-understanding and more effective communication.

- Instantly assess the impact of design changes.

- Best-in-class features to decrease designing time.

- Integrate the latest changes into your workflow while minimizing the learning curve.

Please take a look below for more in-depth coverage of what’s new in the latest release generation of NX.

More Productive Modeling Environment

Our commitment to the investment of core modeling technology provides the world’s most productive modeling environment.

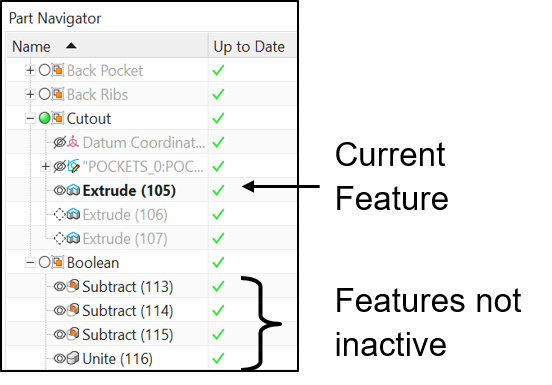

You can easily create complex modifications with our organized features that provide a local edit and update function. These enhancements provide new tools and a faster workflow for machinery designers. The “make current” feature only rolls back features within the active design group and doesn’t make downstream design groups and features inactive.

You can also save time using the Mass Properties Management which automates manual labor and helps you remain immersed in NX. Additionally, NX will automatically update Mass Properties data as you make changes in the design.

In this release you will also find that we’ve streamlined our data navigation with better tools for filtering design data, which allow you to bore through design layers. Additional functionality to the areas of Direct Sketch, Mold Tool & Die, P&ID Designer, Sheet Metal, and Ship Building were also added so that you can explore the “what’s new” tab of NX.

In this release you will also find that we’ve streamlined our data navigation with better tools for filtering design data, which allow you to bore through design layers. Additional functionality to the areas of Direct Sketch, Mold Tool & Die, P&ID Designer, Sheet Metal, and Ship Building were also added so that you can explore the “what’s new” tab of NX.

Generative Engineering

We provide true Generative Engineering and a complete toolset from concept to validation.

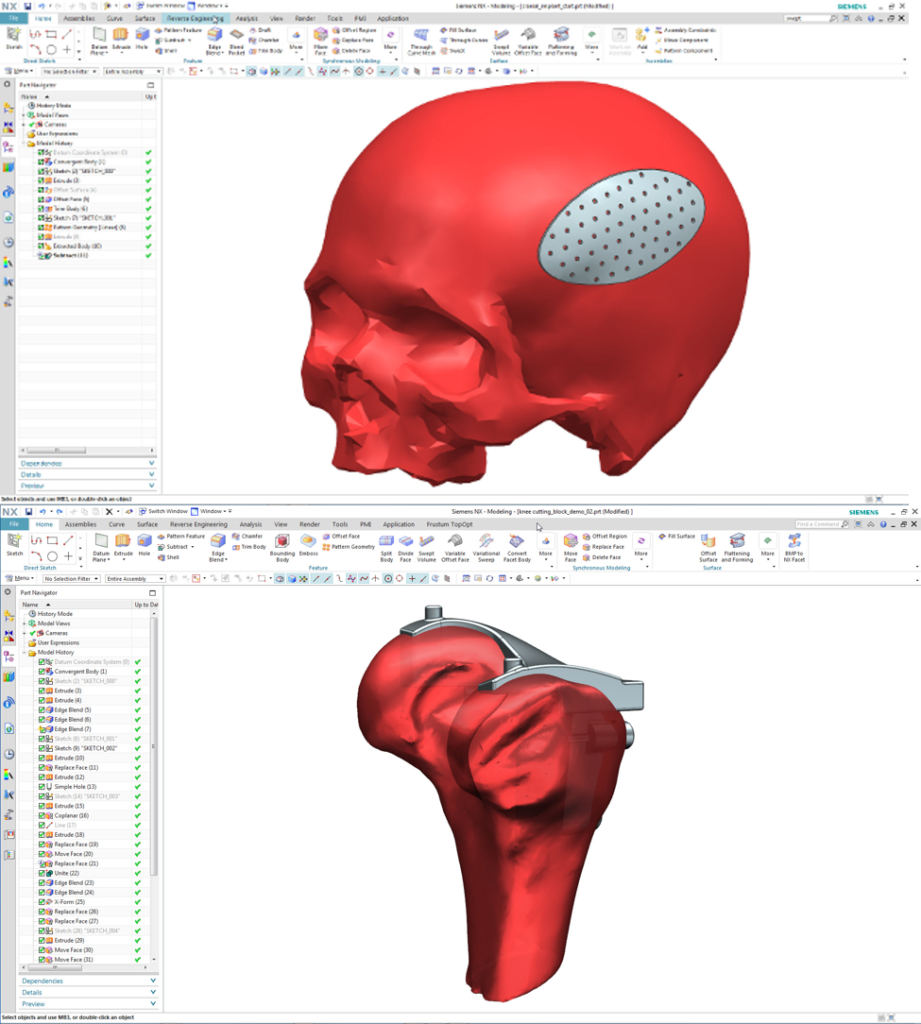

With this update to generative engineering, we’ve added new capabilities to import and prepare point cloud data in NX. This enables importing and meshing of raw point clouds into convergent geometry, which in turn, helps you as a designer to import data into NX and work with it.

Industrialized Additive Manufacturing

75% increase in efficiency is easily attainable.

Productivity of the new tools has a huge impact on your ability to quickly execute programs. We believe in making our tools the most innovative in the market. In fact, over the last 2 years, the NX team has been granted 45 patents to help move forward with increased productivity in workflows. The world’s most productive modeler has an intuitive user interface and the fastest model resolution to help you go from concept to model in the shortest time possible.

The new release can now help you customize lattice load bearing tailored to engineering loads. You can customize lattice support based on FE analysis results, as well as accurately achieving structural needs. All of this can be done simultaneously with capabilities to improve weight management.

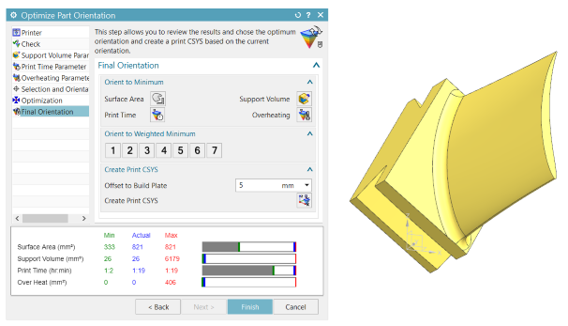

Moving on to the next feature, Optimize Part Orientation. Understanding optimized print orientation helps making the best decisions to design a part. Which is what this functionality has done. It automates the historically time consuming and labor intensive process and optimize the print orientation of the part, weighing multiple design and manufacturing requirements.

More notable enhancements you will notice in our design for additive manufacturing space is our additional checking tools. These persistent checks ensure the parts will be printed correctly and accurately, saving time and effort.

Electromechanical Design

“80% of Product Innovation and differentiation now comes from electrical, electronics and software”

Siegmar Hassis

Daimler R&D CIO

With rich integration of Electromechanical Design, you will notice new additions in this release. You now get a full panel representation in PCB with integration to other applications supports the full digital twin for downstream processes meaning that NX now brings in data from multiple PCB’s (essentially an entire panel) all at once.

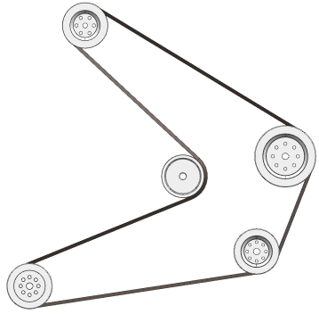

Another addition is the ability to easily setup Pulleys and Belt Chains. These are significant improvements to manufacturing capabilities in concept models and machines. NX has eliminated the need to manually design rigid bodies.

Collaborative Design and Management

“84% of products from best-in-class manufacturers achieve revenue, cost, launch and quality targets using model based definition”

Aberdeen Group

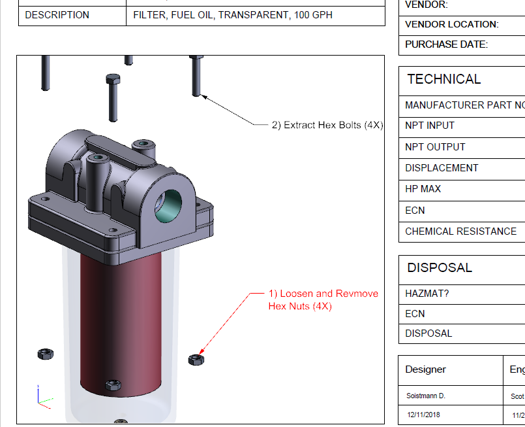

Increase your confidence in collaboration with NX. Streamline your communication with new technical data package options. These new options support collaboration between the suppliers, manufacturers, inspection and quality, assembly, services and other teams requiring access to 3D content.

Through your experience we have provided better enhancements with increased usability to the active workspace. Having eliminated gaps within the Teamcenter rich clients, we visualized arrangements in the Active Workspace which helps provide the ability to open a previous dataset version, and increase the value of Active Workspace clients with NX.

In terms of managing complex products, we have ensured to improve every aspect from our end to achieve this goal. This latest release of NX can help manage the complexities of multi-domain products and track larger number of product and technical requirements throughout the design process.

Integrateing Simulation and Manufacturing

Effortlessly understand and communicate designs

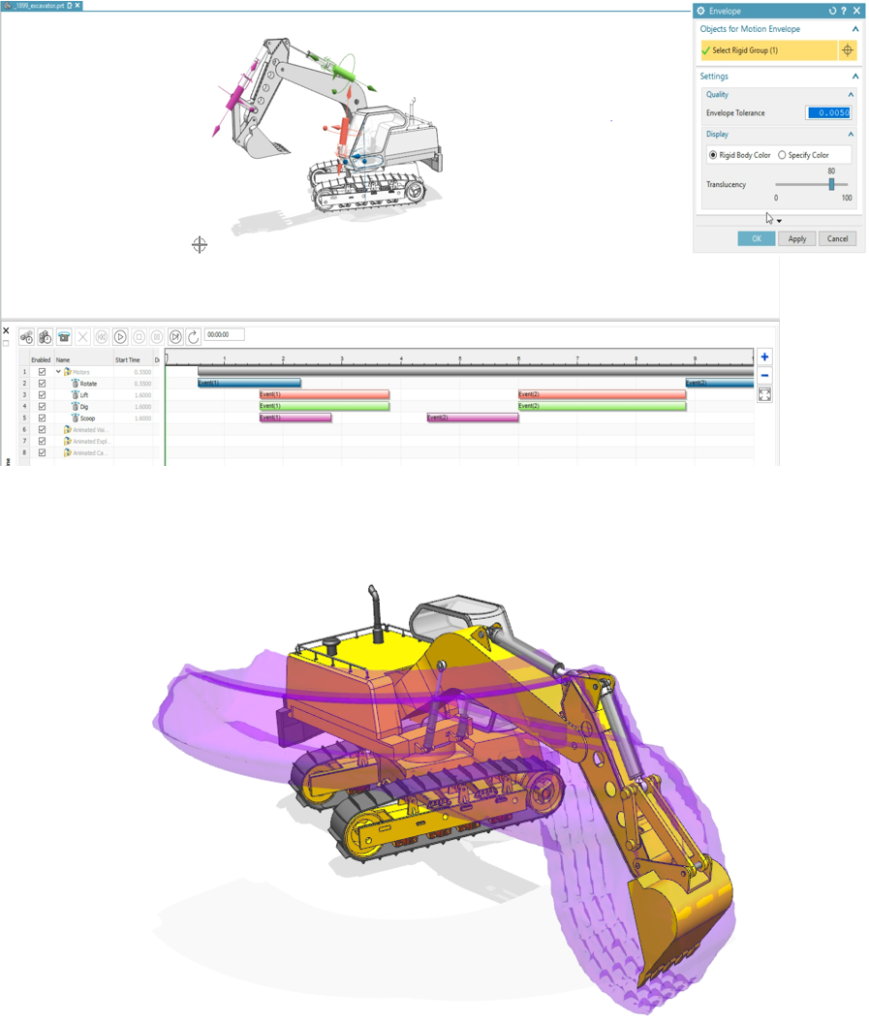

Create and visually see the full path of a component which then help you make necessary modifications based on the results. Having a visual presentation of the component movement path enables better understanding designs. Building around movements will also eliminate iteration steps and achieve faster manufacturing process.

Compared to other PLM products, NX is the only one that allows you to seamlessly go from Design process to Simulation and Manufacturing. All in one software.

NX removes the barriers to innovation

Keep the strongest tools at hand with constant update.

Ensure that the best solutions are in your team’s toolbox with pre-upgrade readiness planning. Design teams can optimize their use of NX and personalized integration for each release.

With this release of NX, we hope to strengthen you and your teams workflows with more efficient modeling capabilities. We’re looking forward to seeing what the world will do with the latest upgrade to NX. Thank you!

Source: Siemens